Innovative technology that keeps your solar panels running while cleaning the modules

Clean the Modules of Your Photovoltaic Plant With No Losses in Power Generation.

Your downtime is causing thousands of dollars in losses. Don't waste any more time or money. With PV WASHER®, you get smart, sustainable cleaning without interruptions.

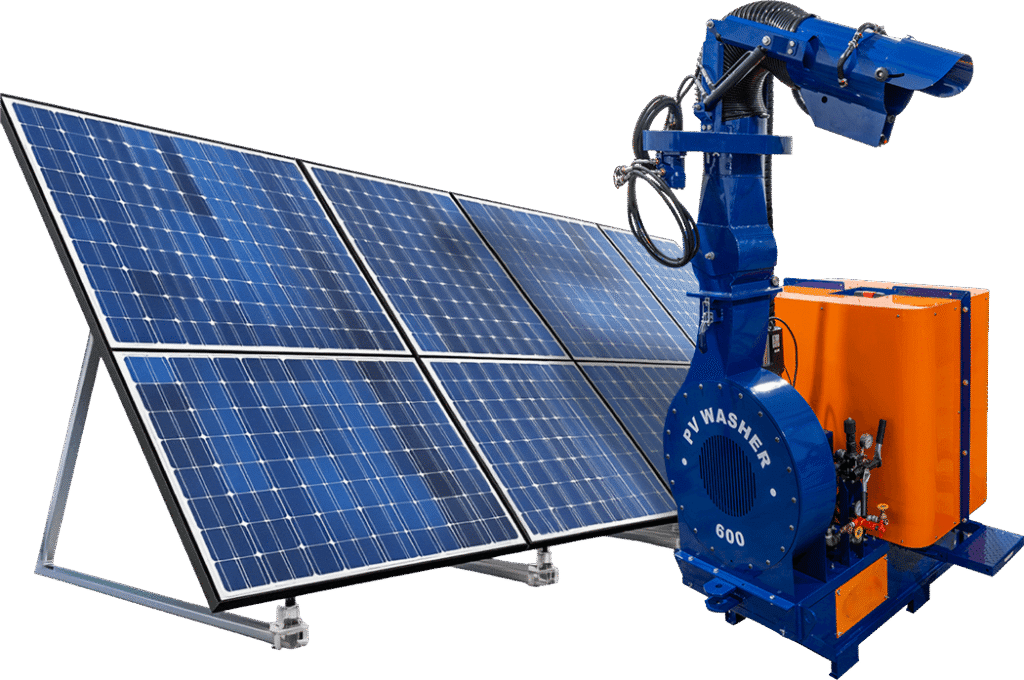

What is PV WASHER®?

An innovative piece of equipment, with patented technology and 100% Brazilian, developed for the efficient and safe cleaning of photovoltaic modules.

Compact, economical and easy to operate, it allows cleaning of solar panels without the need to turn off the system, ensuring maximum energy generation even during the process.

This solution reduces operating costs, minimizes water consumption, reduces labor requirements, and preserves module warranties, offering a quick return on investment and high profitability.

How does it work?

PV WASHER® uses a pressure-controlled air spray method, combined with the addition of just 0.8 to 1.2 liters of water per module, promoting cleaning without direct contact with the panels, avoiding the risk of physical damage.

The equipment is attached to a tractor's PTO, allowing for easy operation and transportation. Its productivity can reach 14,000 to 28,000 modules per day, removing 97% to 99% of dust and fine particles, as recommended by the manufacturers. This process ensures continuous operation, preserves energy generation efficiency, and also contributes to sustainable practices in the photovoltaic sector.

Calculate the estimated annual return by cleaning your plant with the PV WASHER®

Aumente a eficiência da sua usina fotovoltaica, eliminando perdas por interrupção da produção, custos operacionais e riscos de danos aos painéis por limpeza.

Estimated annual return on cleaning

Fill in the 3 fields to see the values.

- Generation of 70 kWh/month per module.

- Dirt accumulates linearly month by month and “resets” after each cleaning.

- Annual return = sum of the return of each cleaning within the year.

An Opportunity to Make More Profit and Preserving your Photovoltaic Modules

The PV Washer®® It is an easy-to-operate equipment, with low initial investment, quick return on investment and high profitability.

1

100% energy efficiency without interruptions during cleaning

2

Protect module warranty and reduce cleaning costs

3

Little labor required to operate the equipment

4

Simple transportation of the PV WASHER® with a small utility vehicle

5

Get a quick return on your initial investment after just a few uses

Who is PV Washer® for?

The PV Washer®® It is the ideal solution for both owners and operators of solar plants, as well as for companies providing cleaning and maintenance services for photovoltaic systems.

Significantly reduces operating costs and protects your investment, ensuring maximum profitability by avoiding downtime and damage to solar modules. Dry cleaning is possible when the soil level is low.

Operational ease and total safety, with lower water consumption and reduced cleaning time, keeping the plant always productive.

Expand your service capacity with high daily productivity, low operating costs, equipment safety, and a fast return on investment.

High profitability opportunity with compact, innovative and easy-to-operate equipment, allowing for a quick return on investment and expansion in the solar market.

main differences that PV Washer® presents

It uses an air and water spray system at a rate of 5 m³/s of air and 0.00125 m³/s of pressurized and controlled water, allowing solar module cleaning without mechanical contact. With quick and convenient operation, the 600 and 1,000 models are directly coupled to a tractor, and the 2,000 and 2,500 models are supplied with the tractor, ensuring total mobility and low operating costs.

Does not interrupt your energy production during cleaning.

Avoids direct contact with the plates, reducing the chances of physical damage.

Low M.O. cost for operation, efficient and sustainable in application.

Equipment technical information

- Wash type: Controlled sprinkling, without direct contact with the module in the proportion of 5 m³/s of air and 0.00125 m³/s of water.

- Water consumption: Approximately 1.2 L/module (single axis) or 0.8 L/module (dual axis).

- Productivity: Washes 33 m/min (single axis) or 74 m/min (double axis), reaching 14,000 to 28,000 modules/day.

- Effectiveness: Removes 97% to 99% of dust and fine particles, as recommended by module manufacturers.

- Compatibility: Fixed structures or trackers (single/dual axis), including bifacial modules and trackers with connecting rod.

- Model 600 and 1,000 drive: Universal tractor power take-off (PTO), facilitating transportation and use.

- Drive models 2.000 and 2.500: Skid on articulated tractor.

- Dimensions and weight model 600: Approximately 1.15 m (width) × 1.57 m (length), weighing about 465 kg empty.

- Dimensions and weight model 1.000: Approximately 1.45 m (width) × 1.57 m (length), weighing about 465 kg empty.

- Dimensions and weight models 2.000 and 2.500: Approximately 1.75 m (width) × 5.46 m (length), weighing about 675 kg empty.

- Autonomy: Available in capacities of 0.6 m³, 1.0 m³, 2.0 m³ and 2.4 m³, enabling cleaning or cooling.

- Working pressure: Controlled, aligned with panel manufacturers’ specifications (no risk of damage).

- Continuous operation: Does not require the plant to be shut down during washing, avoiding generation losses.

- Reduced team: It only requires 1 operator (tractor driver) and 1 assistant.

- Low maintenance: Includes periodic checking of belts, filters and pump oil changes.

- Reversible wash: You can wash from the front or from the rear, if front access is limited by a connecting rod.

- Additional MOP: Helps remove aesthetic stains from embedded dust, when requested.

- Warranty Preservation: Contactless washing minimizes the risk of microcracks and damage to modules.

Download our information brochure

PV WASHER® and discover more details (Available in Portuguese, English and Spanish)

Questions and answers about the PV Washer®

The PV Washer®® Reduces water consumption, labor, and cleaning time. Avoids mechanical contact with the modules, protecting them from microcracks, and performs cleaning without needing to shut down the power generation system.

No. It cleans the modules through controlled spraying, without direct physical contact, protecting them against the risk of micro-cracks or structural damage common when cleaning with brushes or squeegees.

No. One of its greatest advantages is that it allows cleaning without interrupting energy production, ensuring continuous plant efficiency throughout the entire process.

The operation requires only one operator (tractor driver) and one assistant. A plant of up to 5 MW can be completely cleaned in just one or two days, depending on the terrain conditions and size of the facility.

It uses an optimized sprinkler system, significantly reducing water consumption (on average 1 liter per module), without the use of chemicals, protecting the environment and promoting sustainability.

The PV Washer®® It is highly effective in periodically removing fine dust, dew, and common environmental debris. For stubborn dirt like bird or insect droppings, a dedicated mop can be used as needed.

Yes, by cleaning only with an air jet, providing good performance for modules with low dirt or preventive cleaning.

Yes, the PV WASHER® It's compatible with fixed structures, single- or dual-axis trackers, and bifacial modules. Its multidirectional cannon allows for front or rear cleaning, adapting to any configuration.

The PV Washer®® It has an estimated average durability of 10 years, with simple and economical maintenance, including periodic oil changes, belt inspection, nozzle cleaning and lubrication as indicated in the manual.

contact us

Leave your message below for more information or a quote from PV WASHER®® for your business.

- R. Ver. Anthero Joaquim Santiago, 821, Europark, Indaiatuba/SP

- geraldo.dias@pvwasher.com.br

- +55 (19) 99770-5090

A leader in innovative technological solutions for the photovoltaic sector, we offer high-performance equipment that increases productivity, reduces operating costs, and promotes sustainable practices.

Patent Process:

BR 10 2021 015893 0

Related services and terms

- Cleaning solar panels

- Photovoltaic maintenance

- Savings in solar generation

- Reduction of operating costs

- Quick cleaning of solar modules

- PV Washer JD Equipment

- Solar sprinkler system

- Preservation of solar modules

- Operational safety in solar power plants

- Mechanized cleaning of solar panels

- Preservation of the warranty on solar modules

- Cleaning without shutting down the solar plant

- Dry cleaning of solar panels

Contact

If you have any questions, please contact us using the numbers below:

- R. Ver. Anthero Joaquim Santiago, 821, Europark, Indaiatuba/SP

- geraldo.dias@pvwasher.com.br

- +55 (19) 99770-5090

JD EQUIPAMENTOS LTDA – CNPJ 05.815.181/0001-28 © 2025 All rights reserved

Developed by MHB RAFFA DESIGN AND DIGITAL MARKETING